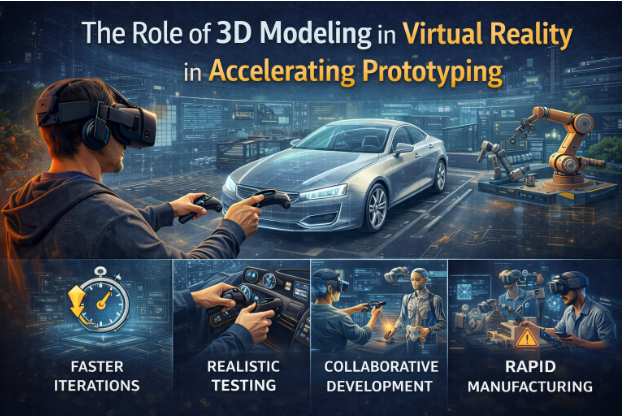

Prototyping has always been one of the most important phases of the design and engineering process. This is essentially the point where concepts and ideas undergo testing and development before being produced.

Nevertheless, traditional prototyping has always presented processes that involve long development periods and high costs. With innovation schedules becoming smaller and smaller, designers and engineers are relying on 3D modeling in virtual reality for faster and more efficient prototyping.

Because virtual reality technology allows designers and engineers to work with concepts within a digital environment, the process of going from concepts to validation has been greatly eased. This technology is revolutionizing the process of creating prototypes and testing them.

Rethinking Traditional Prototyping Challenges

Traditionally, prototyping is done either through physical models or simulation on a computer screen. Although it is quite effective, it poses some setbacks in the form of time consumed through material processing, lack of flexibility, and rebuilds. Design changes may call for a fresh prototype.

How Virtual Reality Increases the Speed of Prototyping

The main benefit of an immersive workflow is based on real-time interaction. With the help of virtual reality for three-dimensional modeling, prototypes are designed, changed, and assessed in a virtual environment instantly. There are no more waiting times for physical prototypes or still images.

This enables rapid iteration. Problems in designs, conflicts in space, as well as usability problems are identified early in this process. This allows for quick changes without having to start over in the prototyping phase. It is now possible to complete several iterations in the time it used to take to create one physical prototype.

Increasing Accuracy of Early Prototype Evaluation

Common issues that early prototypes might have could be related to accuracy in terms of size, proportion, or functionality. Screen-based assessments involve the designers anticipating the performance of objects within real-world scenarios.

Virtual reality takes the guesswork out of this process by allowing the prototype to be the actual size. The teams can walk around the designs, which gives them the same feeling as if the designs were already developed. The process is much more accurate.

Minimizing the Need for Physical Prototyping

Physical prototypes require expensive production and are difficult to modify. Even though their use still continues in final validation, their use at the early stages could hold up development.

The immersive digital prototyping technique also lessens the number of models that must be created physically. The fact that models can be created digitally enables validation of concepts without investing in their physical creation. The technique also saves on material as well as hastens the prototyping process.

Facilitating Cross-Functional Collaboration

Prototyping may require the involvement of designers, engineers, product managers, and clients. A miscommunication between the parties may cause rework and may lead to delays.

Virtual reality allows all stakeholders to examine prototypes simultaneously in the same environment. All stakeholders see the same prototype at the same time and from the same viewpoint. Many companies partner with a professional firm for 3D visualization of the prototype so that the prototype functions properly in real time.

Usability Enhancement and Ergonomic Assessment

Functionality and usability are important parameters in successful prototypes. Ergonomic analysis in sketches or screens can be difficult in the case of a product or space that is meant for human interaction.

Immersive environments enable teams to conduct simulations of real-world usage. Mobility, reach, visibility, and comfort can all be tested in the early stages of prototyping. This goes a long way in determining usability problems before going into production.

Reducing Cycle Time in Area Updatings

One of the biggest sources of delay during the prototyping phase has to do with the process of review and approval. It can be difficult for stakeholders to understand the prototype without having access to technical visuals.

Virtual reality allows the prototype to be explained and understood, both by technical and untrained individuals. Communication is therefore enhanced, resulting in approvals being given within a short period since the person understanding the technology is more confident.

Encouraging Innovation via Rapid Experimentation

Innovation is the result of experimentation. But traditional prototyping tends to constrain the possible ideas to a very small set because of limitations of cost and time.

Instead, because immersive digital tools enable teams to test different variations efficiently, teams can compare and improve designs in the course of the same meeting. All this fosters creativity and results in better final designs.

Creating Long-Term Value Beyond Initial Prototyping

The advantages of immersive prototyping methods and tools can be extended even in later development stages. The virtual prototype developed has multiple uses, such as presentation, training purposes, and even in future designs. This is an added value to the investment made in immersive modeling solutions.

With the advancements in tools, the concept of a virtual prototype is becoming a seamless part of the product and project process, rather than a one-off deliverable.

Conclusion

Speed and precision when it comes to prototyping have become a necessity today due to the rapid pace of life in the design and engineering industry. 3D modeling in virtual reality is playing a vital role in speeding up prototyping processes. With the help of a skilled 3D visualization company, prototyping is likely to be more accurate.

While the pursuit for efficiency and innovation continues in industries, prototyping based on virtual reality is no longer an experimental process. Rather, it has become a solution that is future-oriented, enabling a collaborative process that helps move faster, make better decisions, and produce better outcomes.